Plastic moulding

With injection moulding, plastic that is supplied as granules or powder is melted into a liquid mass and injected under high pressure into a mould whose cavity is the shape of the desired product. After cooling of the plastic, one gets the desired product.

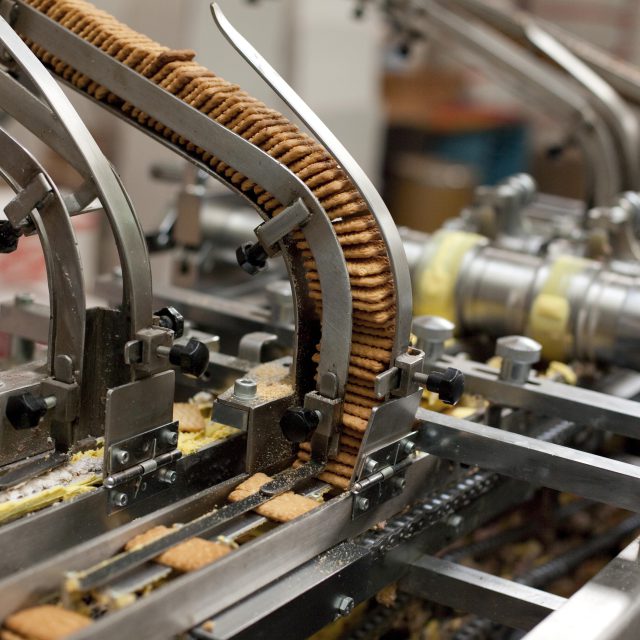

Injection moulding is one of the most widely used moulding techniques for plastic parts. Materials such as POM, PP, PA, ABS, PMMA, PC, PE, ASA, …. belong to our range. Certain plastics are just as strong at a temperature of 150 degrees and are therefore very suitable for the food industry.

Advantages

- Retains its strength under the influence of temperature changes

- Suitable for both mass production and smaller series

- Influenced product hardness

Applications

Plastic injection moulding is used to manufacture products for packaging, consumer goods and industrial applications. But there are also many opportunities for plastic injection moulding in the automotive and equipment industries.