Low pressure die casting

In low pressure die casting, a permanent metal mould is used, consisting of two or more parts fitting together, the cavities of which correspond to a model of the object to be cast. The casting with the corresponding moulding system must be ‘loose’ in order to be able to remove the casting from the metal mould.

The mould is manufactured from cast iron blocks by various machining operations. The durability of the mould is determined by the size of the product, the shape and the complexity. Before casting can be carried out, coatings must be applied. Different coatings are used for different parts of the mold in order to stimulate or inhibit local solidification.

Advantages low pressure die casting

- The availability of a permanent mould. This avoids high raw material costs, as in sand casting and precision casting, where a new mould is made for each new casting.

- The casting has good dimensional accuracy.

- Relatively low investment compared to high-pressure casting.

- Environmentally friendly production technology.

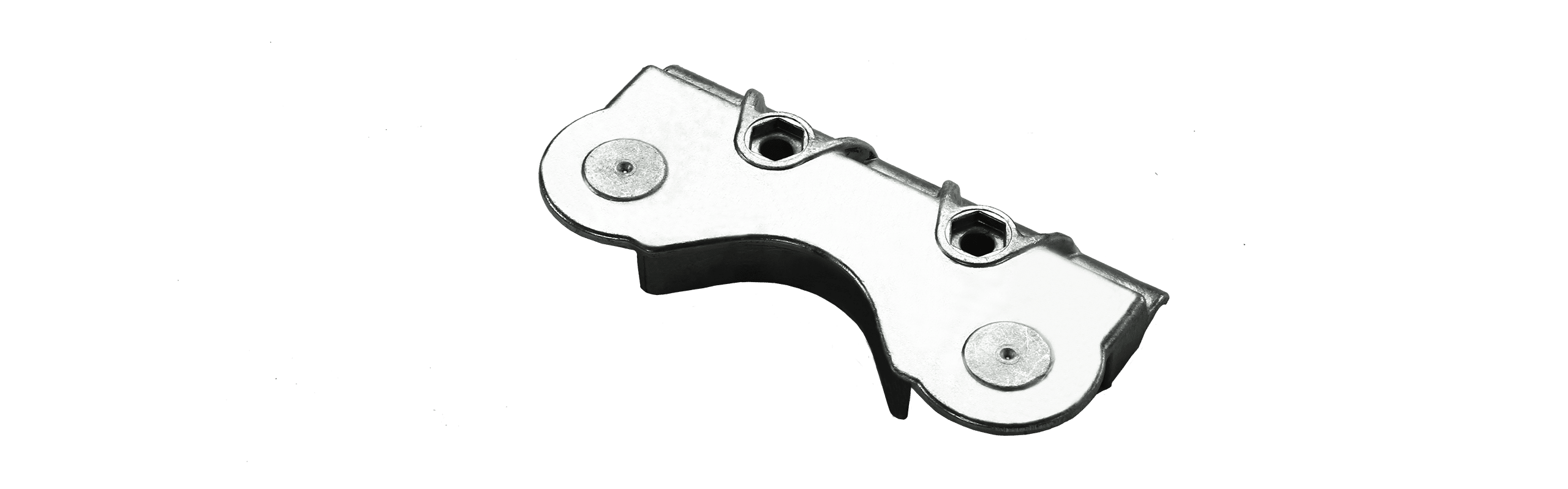

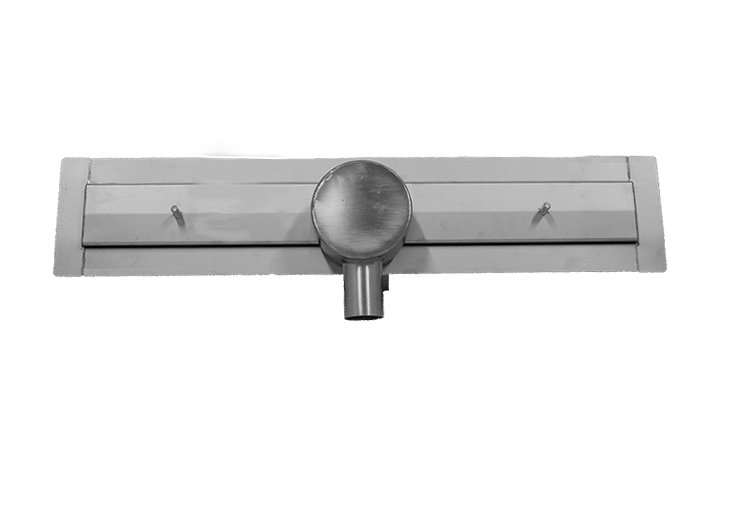

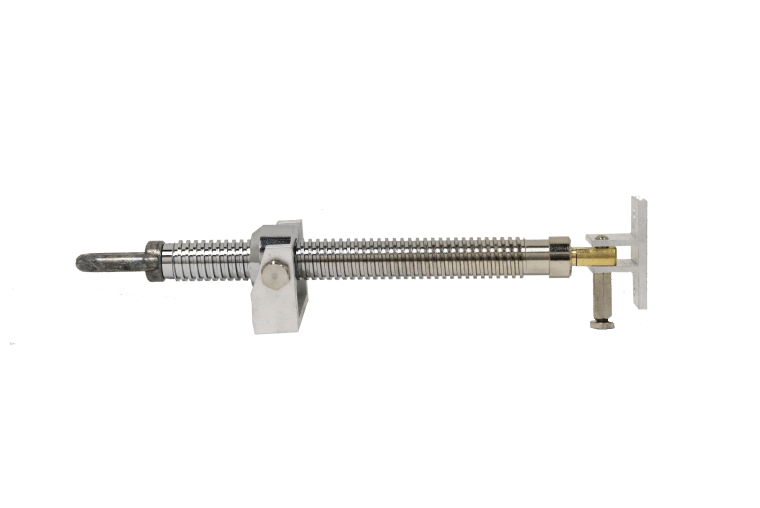

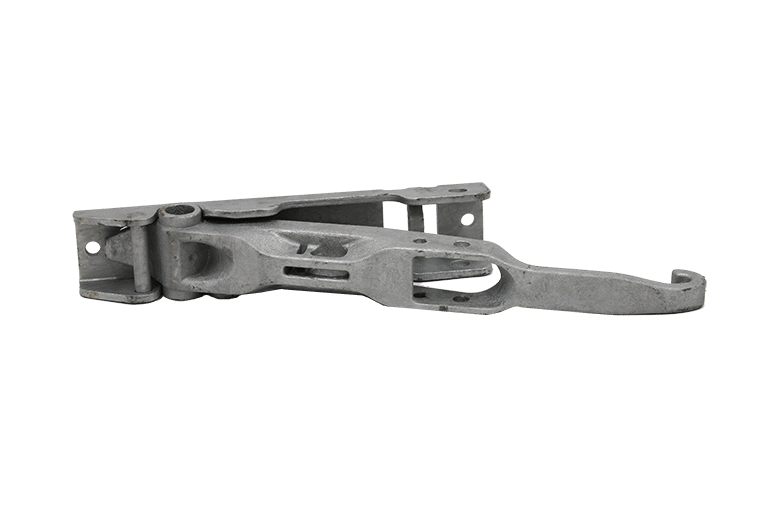

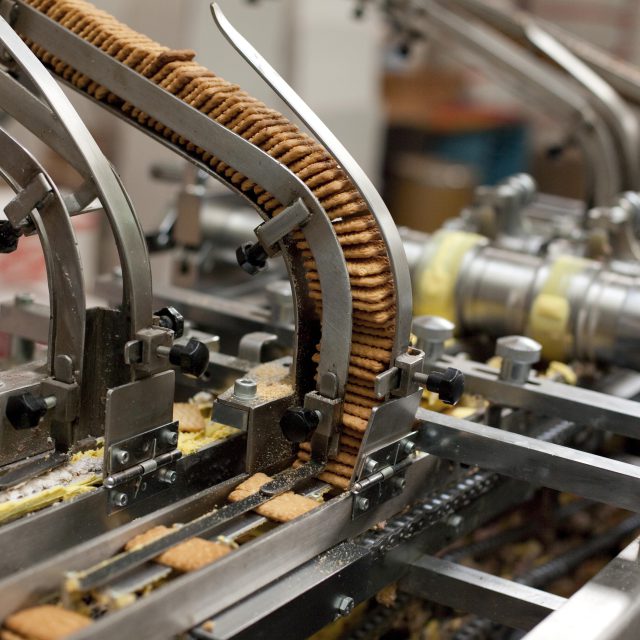

Applications low pressure die casting

Low pressure die casting is mainly used in the construction, logistics and agricultural sectors.