Lost-wax casting

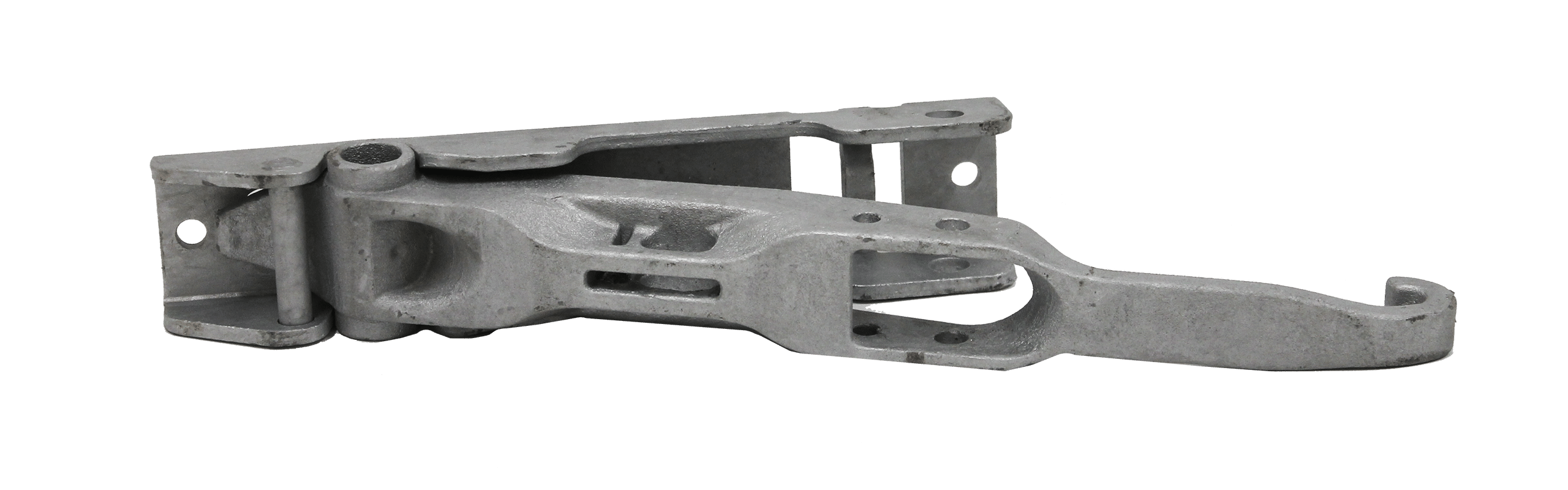

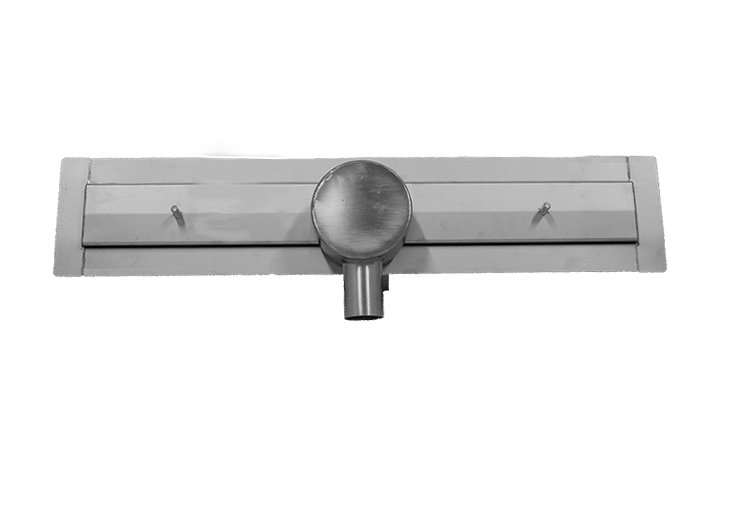

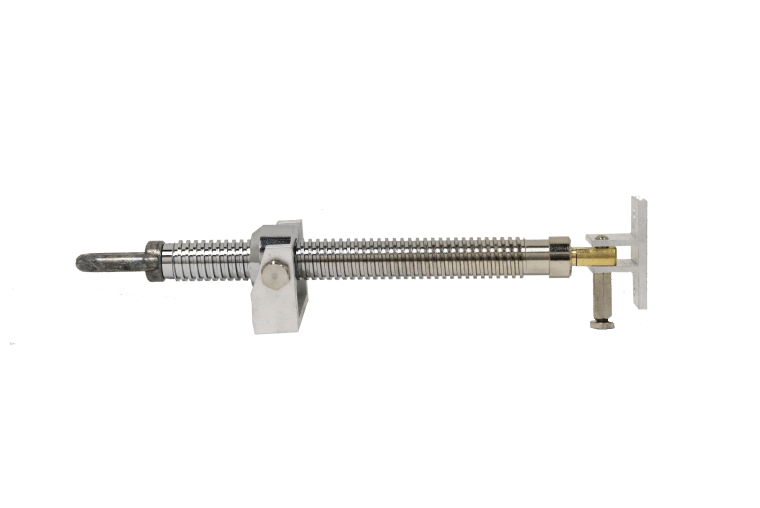

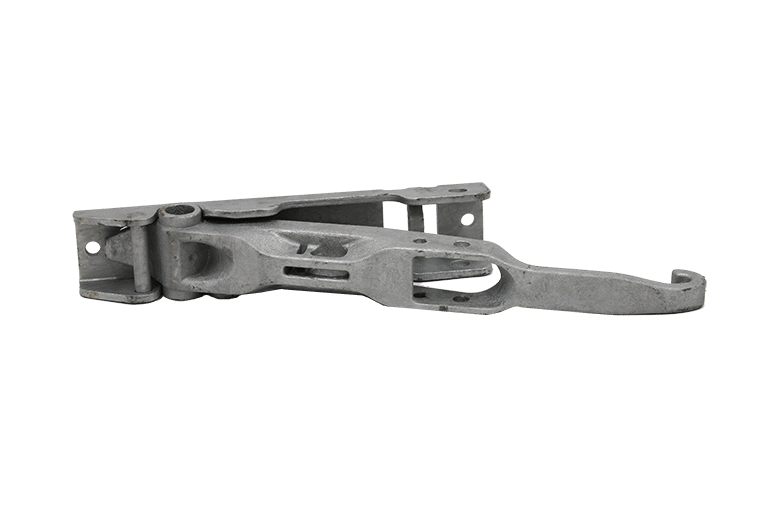

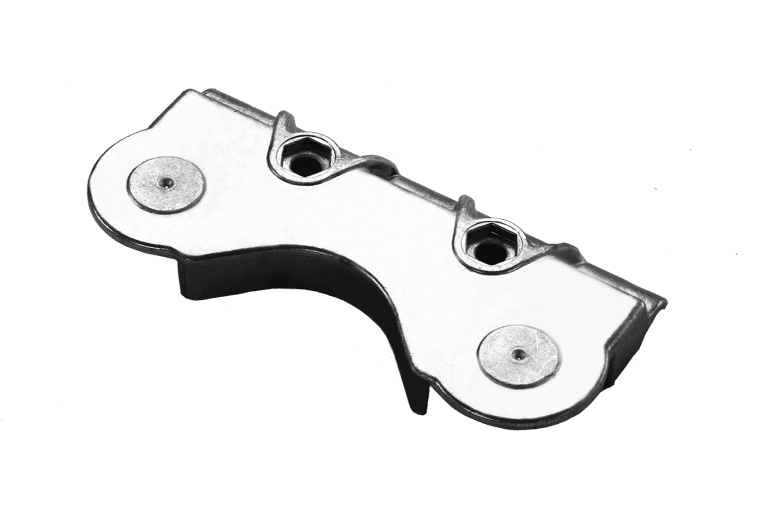

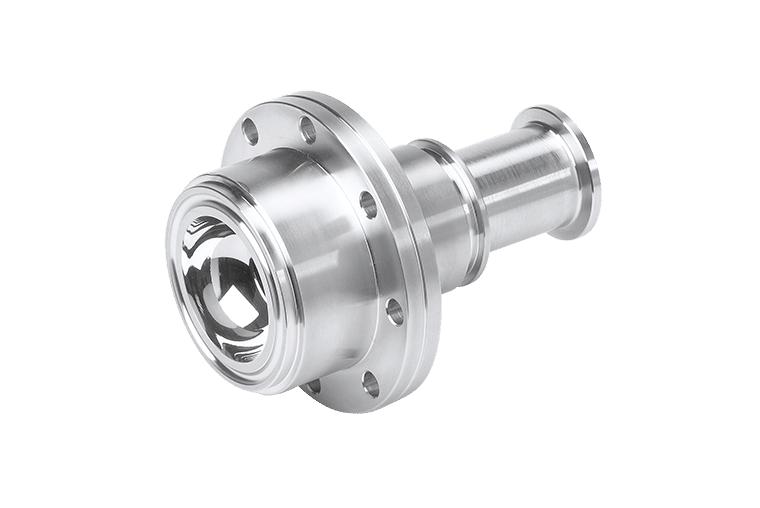

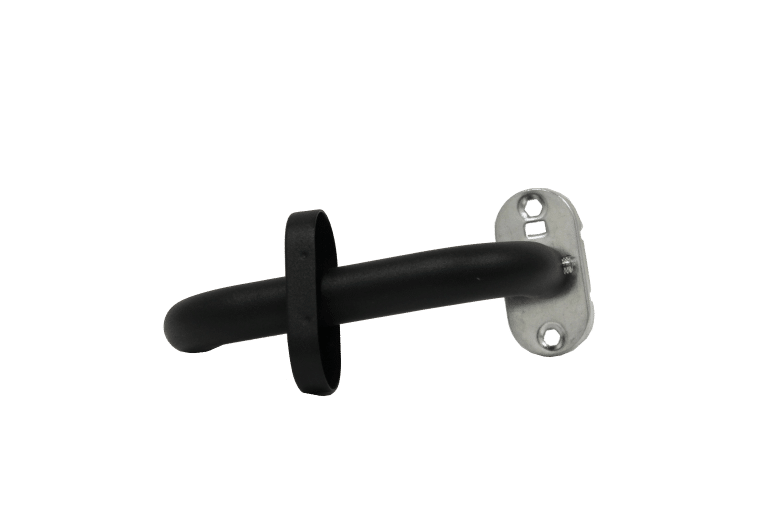

Lost wax casting is an industrial-scale method for casting precision parts in high melting point metal alloys. Lost wax casting is the most accurate of all casting processes, with machining reduced to a minimum.

Advantages

- Large freedom of form

- Possible to cast complex shapes. This makes it possible to avoid assemblies (screws, welds, etc.) and to save weight.

- Finishing operations are necessary, which significantly reduces production costs

- Good surface properties (Ra. = +/- 3,2 µm)

- Limited tool investment, making this casting method also usable for smaller series.

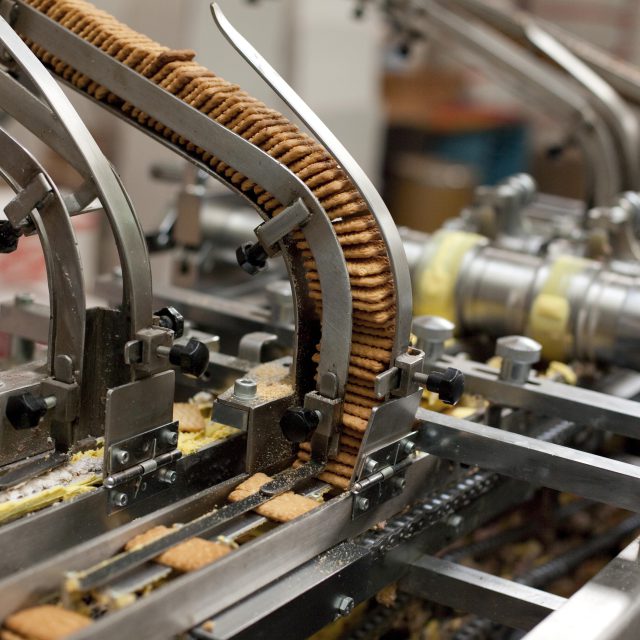

Applications

This technique has a very wide range of applications in almost all branches of industry (food, automotive, shipping, piping, machine construction, tools, engines, agriculture, defence, aviation, building hardware, etc.).