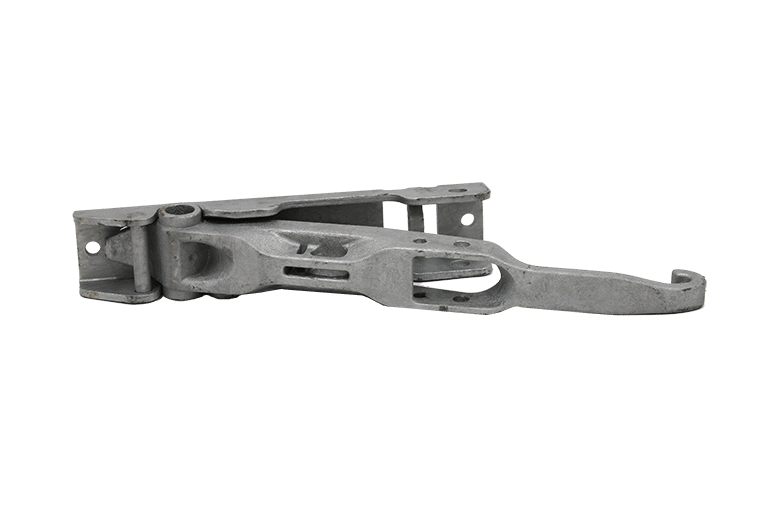

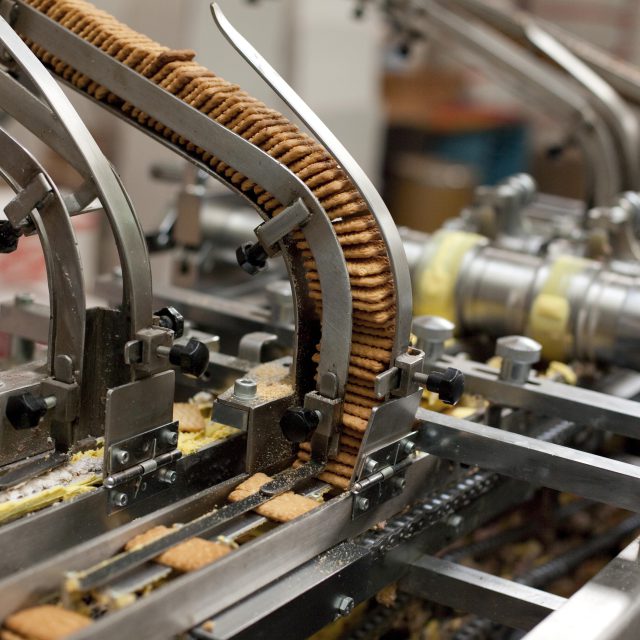

Forging

Forging has a different heat-forming method than casting. In forging, the steel is heated in an oven, making it malleable. It is then pressed into a steel mould consisting of two parts. With this production method, no core cavities can be realised. A piece of forging is therefore always solid. This is a limitation of forging compared to casting. An advantage of forging over casting, however, is that it is considerably less expensive than casting in, for example, cast steel if good welding characteristics are desired.

Advantages

- Consistent dimensional accuracy

- Homogeneous material with mechanical properties

- High production speed in large series

- Cost-effective for large series

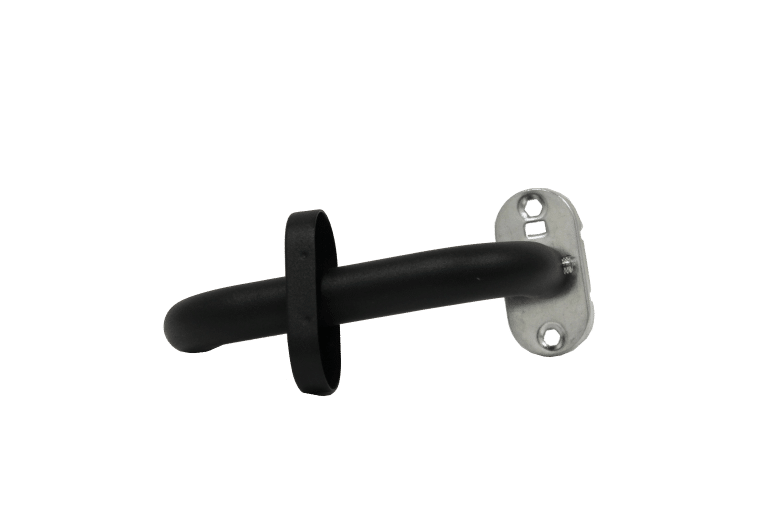

Applications of forgings

This technique is widely used in various industries. A recognisable example is a hook in the construction industry or an anchor in the shipping industry.