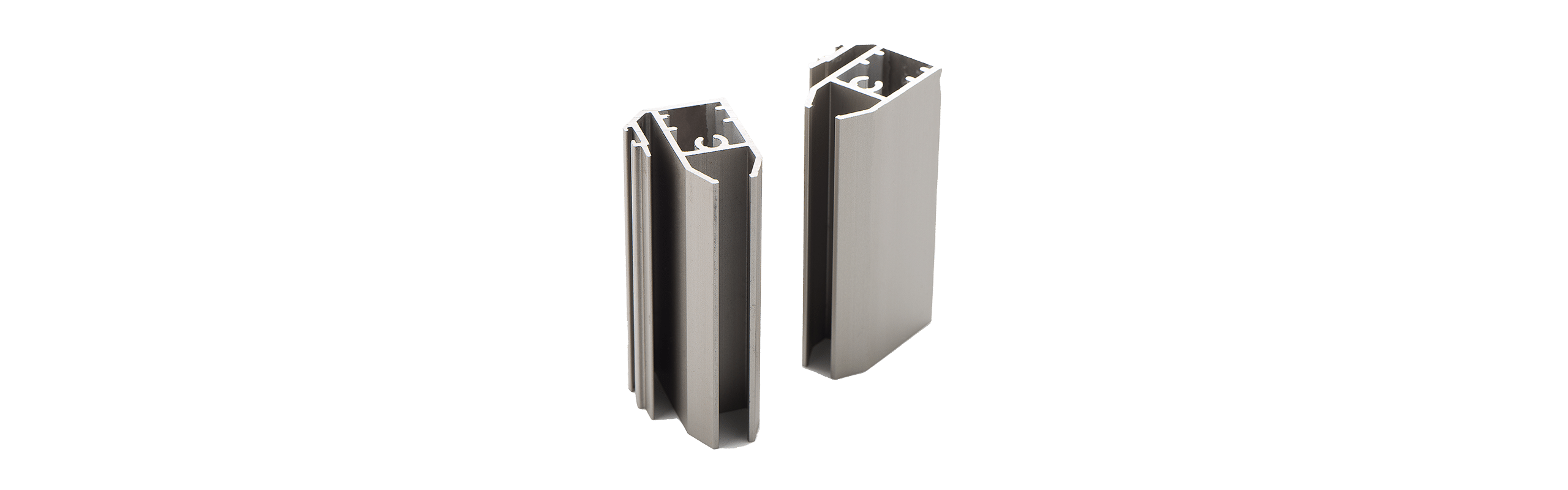

Aluminium extrusion

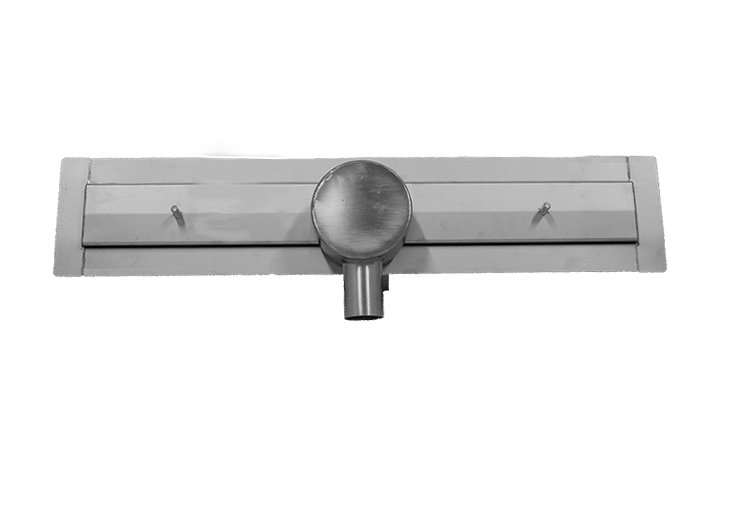

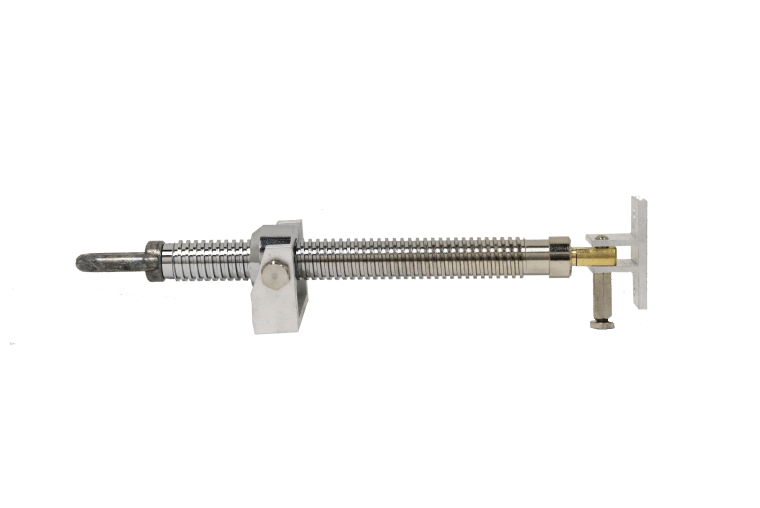

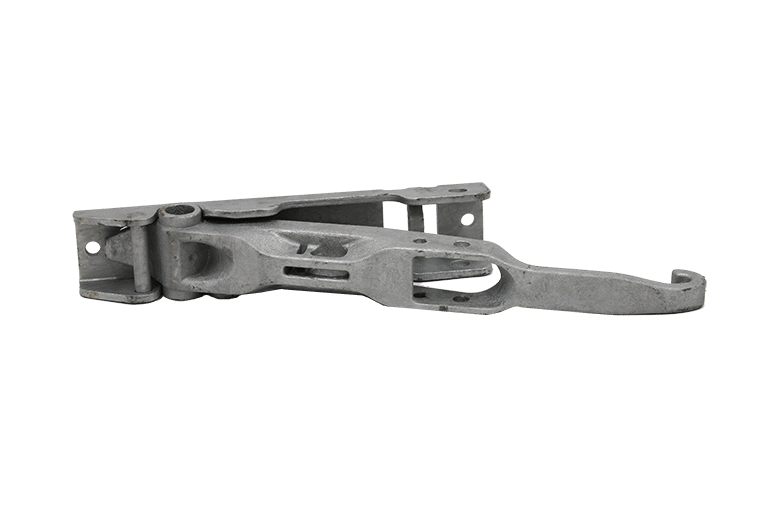

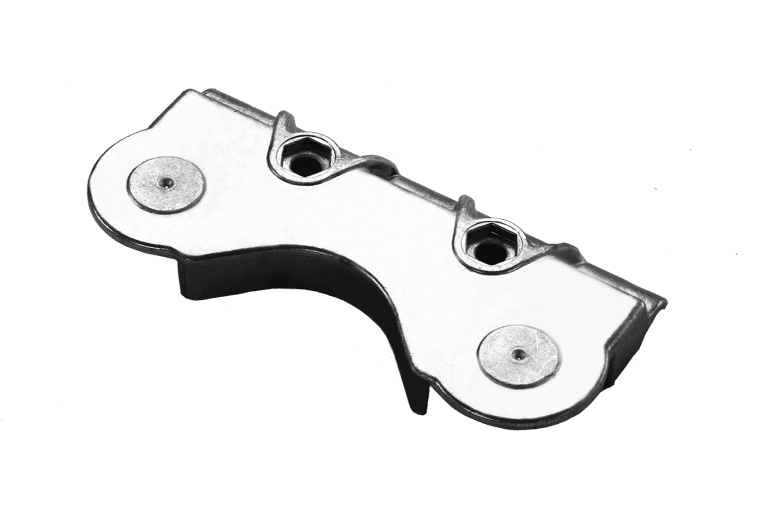

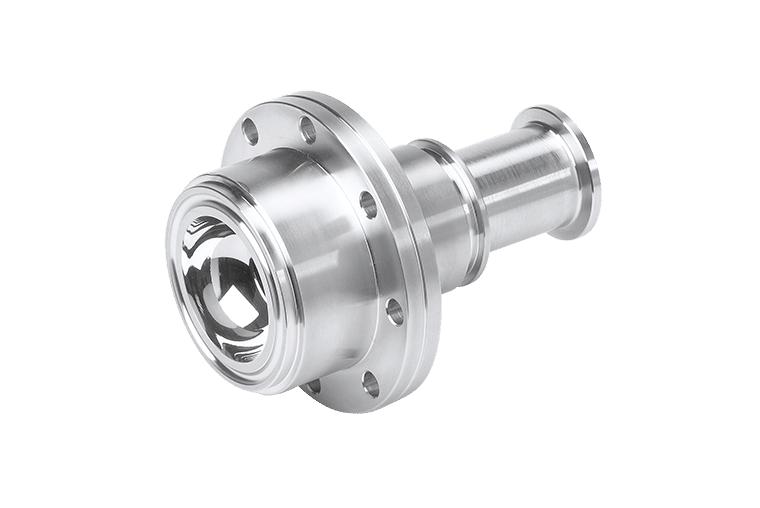

Apart from rolling, aluminium extrusion is one of the most common forming techniques used in aluminium forming. The aluminium alloys used fall into the category of “kneading alloys”. By pressing a hot block of aluminium through a mould, all shapes can be made. Both “hollow” and “solid” profiles are possible. Profiles with a metre weight of over sixty kilograms can be pressed using this method. The addition of functions is almost unlimited with extrusion, whereby knowledge and experience play an important role.

Advantages aluminium extrusion

- The range of product forms is virtually unlimited

- Relatively few parts are used, which lowers costs and speeds up the production process

- Process reliability and reproducibility

- Multiple profiles can be pressed in 1 press

- Thin wall thicknesses are also possible, which can reduce the price/kg

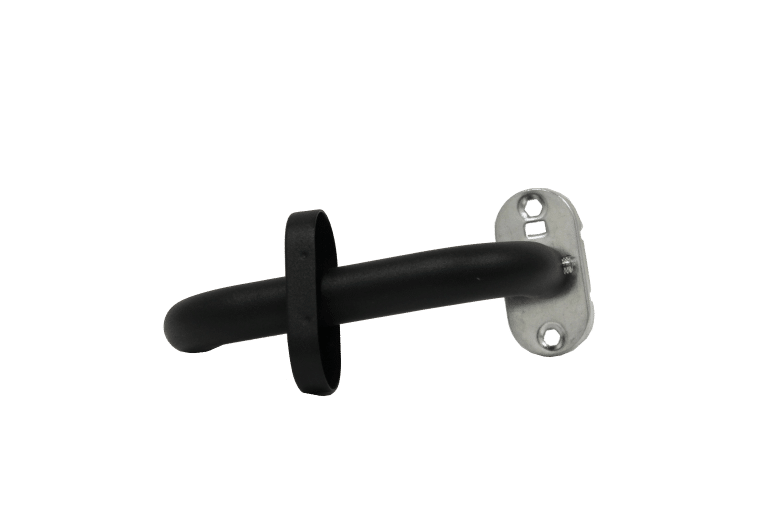

- Functionalities can be built into the profile (hooks, eyelets, slots, etc.)

- Additional mechanical properties are possible due to aging

- Aluminium has a very good weight/strength ratio

- Aluminium extrusion allows aluminium to be provided exactly where extra strength is needed

- Aluminium profiles have good mechanical properties

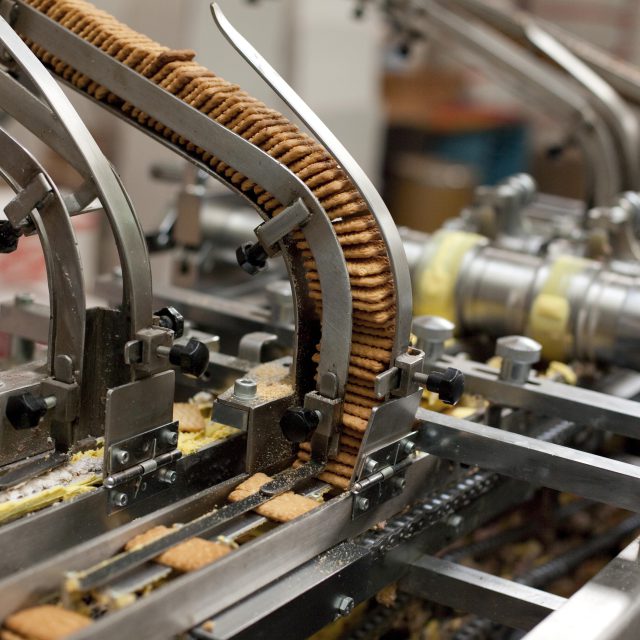

Applications aluminium extrusion

The automobile industry, aircraft industry, shipbuilding, machine building, construction, bicycle industry and the medical sector are all sectors where aluminium extrusion is used.