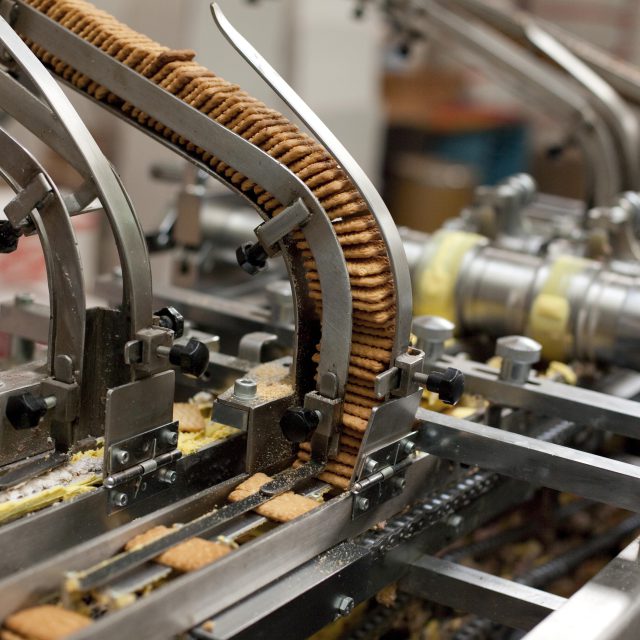

Plastic extrusion

Plastic extrusion, like aluminium extrusion, is a manufacturing process in which raw plastics are melted and then formed into a continuous profile by pushing it through a die. The most common extrusion materials are PVC, PP, LDPE, HDPE, polystyrene, polycarbonate, acrylic, nylon, polyacetal, acrylonitrile butadiene styrene and elastomers.

Advantages Plastic extrusion

- Versatile and can be used for products that have to meet specific technical requirements

- Lightweight, which ensures lower transport consumption

- Resistant to chemicals, water and external influences

- Safe and hygienic for food packaging

- Excellent thermal and electrical insulation properties

- Lower energy consumption and CO² emissions during production compared to a mix of alternative materials such as glass, metal, etc.

Applications Plastic extrusion

Plastic extrusion is especially useful for manufacturing window frames, pipes, draught strips. Therefore, plastic extrusion is mostly used in the consumer industry and construction sector.