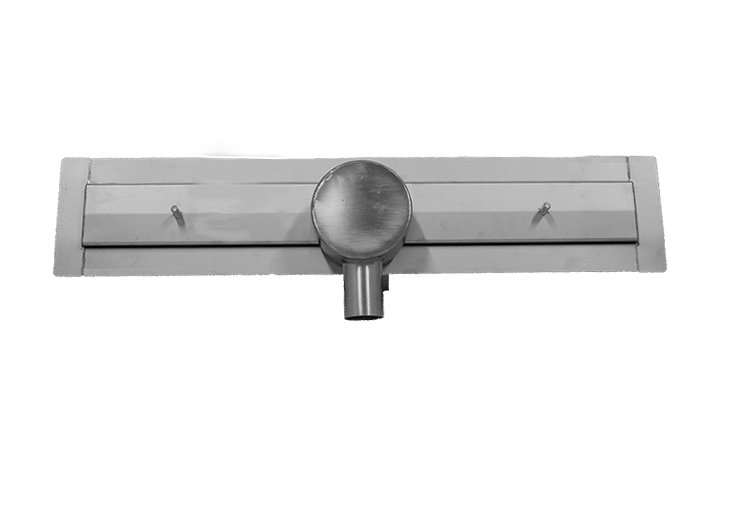

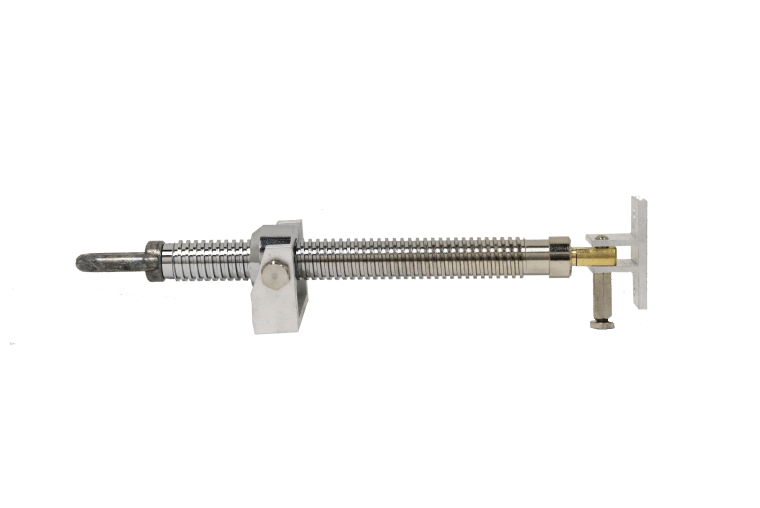

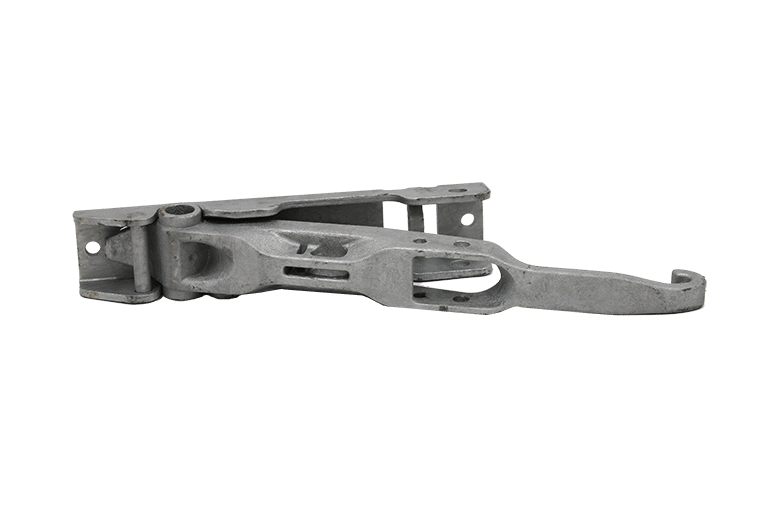

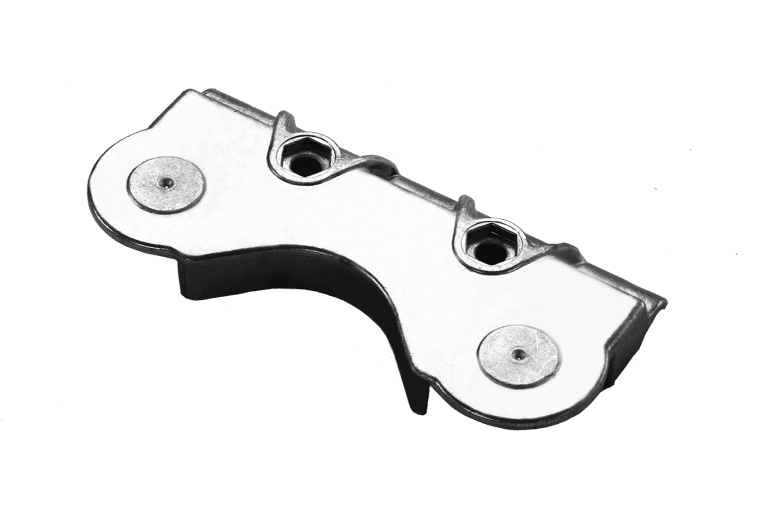

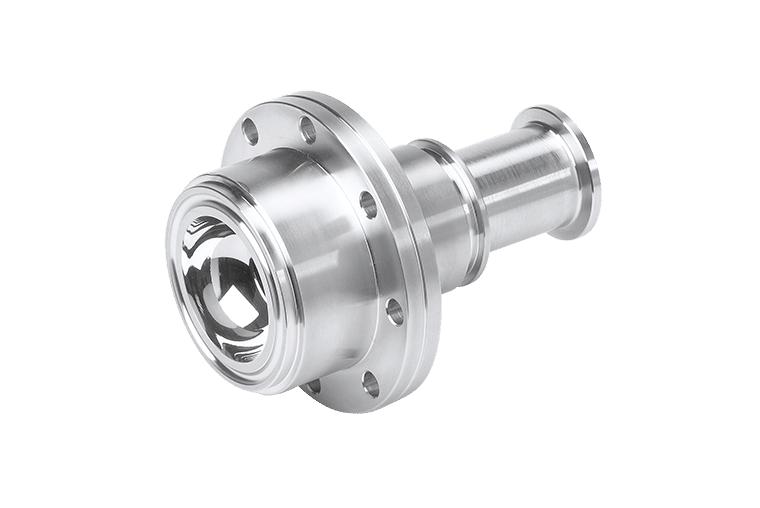

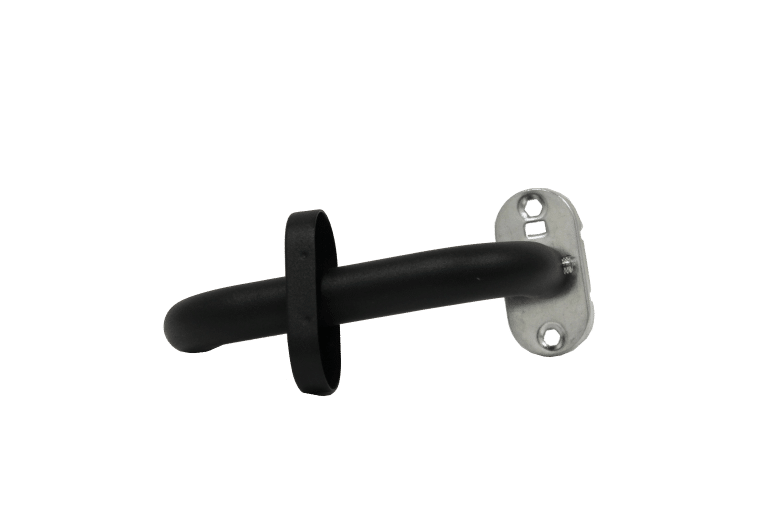

Aluminium casting

Aluminium is very good for casting or liquid shaping. When casting, a product is created because liquid aluminium, after solidification, assumes the shape of the form (mould) into which it is cast. The final shape is approximated as closely as possible so that hardly any post-processing is required. By casting, we are able to shape a product so that it exactly meets the shape and requirements of our customer.

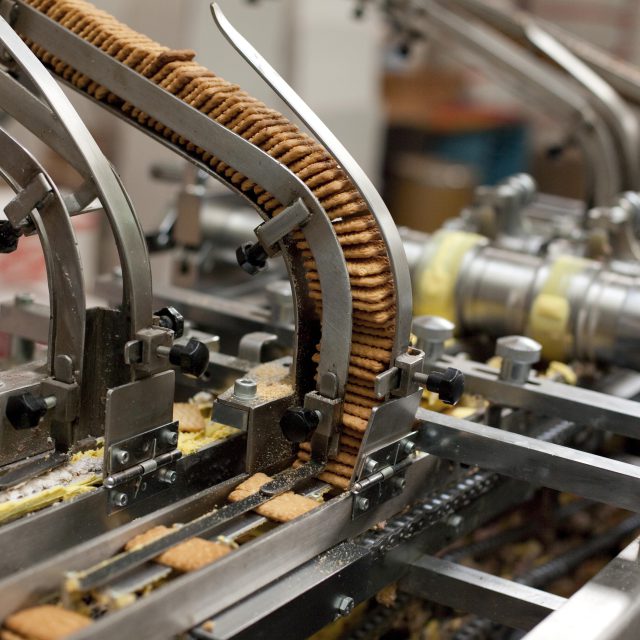

Applications aluminium castings

Aluminium castings are used in the following sectors: automotive industry, aircraft industry, shipbuilding, machine building, construction, bicycle industry and the medical sector.

Advantages aluminium castings

- Large weight savings

- High dimensional accuracy (depends on the process used)

- Enormous freedom of shape

- Good machinability

- No cold brittleness at very low temperatures

- Good recyclability, therefore high residual value

The available casting methods for aluminium casting are:

- Sand casting

- Low pressure die casting

- Low- and high-pressure injection moulding

- Vacuum foil casting

- Lost wax and foam casting

- Investment casting

- Shell moulding